Introduction

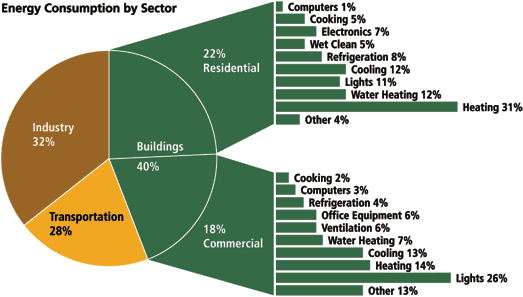

In 2009, building operation was responsible for about 30% of greenhouse gas emission and accounted for about 40% of primary energy consumption globally [1]. Furthermore, greenhouse gas emission from the building sector is expected to grow in the next decades as a result of rapid economic growth [2]. Similar statistics hold for the United States. In 2011, building operation accounted for about 40% of total US primary energy consumption with 46% consumed by commercial and 54% by residential buildings [3]. About 30 and 43% of this energy was consumed for space heating and air conditioning in commercial and residential buildings, respectively [3]. Therefore, reducing the energy required for heating and cooling would substantially improve building energy efficiency. To curb the energy consumption of the building sector, the 2008 California long term energy efficiency strategic plan established two major goals: (1) all new residential buildings should be zero net energy (ZNE) by 2020 and (2) all new commercial buildings by 2030 [4]. The European Union established similar goals: (1) new buildings owned and occupied by public authorities will be “nearly ZNE” by 2018 and (2) all new buildings will be “nearly ZNE” by 2020 [5].

Composite cementitious materials containing microencapsulated phase change materials (PCM) have been suggested as a way to increase the buildings' thermal inertia and thus their energy efficiency. PCM are distinguished from traditional thermally massive materials, as they store energy in the form of latent heat by reversibly changing phase between solid and liquid instead of storing energy as sensible heat. One advantage of latent over sensible heat storage is the relatively large energy storage capacity per unit volume. The goal in implementing composite PCM walls is to significantly reduce and time shift the maximum thermal load on the building in order to reduce and smooth out the electricity demand for heating and cooling, as shown in Figure 1. This could help ratepayers take advantage of time-varying electricity rate schedules while reducing the ecological footprint of buildings.

Phase Change Materials

Phase change materials (PCM) transitioning between solid and liquid states near room temperature have been used to enhance the thermal storage capacity of traditional building materials. They store thermal energy in the form of latent heat when subjected to temperatures in excess of their melting point. PCM can be divided into three categories: organic, inorganic, and eutectic. Organic PCM consist mainly of paraffins and fatty acids. Paraffins are straight-chain hydrocarbons with the general chemical formula and are a by-product of oil refining. They can be categorized based on purity as technical (~95% pure) or laboratory grade (> 99% pure), but cost considerations limit commercial use to technical grade paraffins. Inorganic PCM are typically either salt hydrates or metallics. Lastly, eutectics are mixtures of two or more PCM and can be any combination of organic and inorganic constituents. Table 1 summarizes the advantages and disadvantages of organic and inorganic PCM.

Numerous reviews have summarized the thermophysical properties of commercial and laboratory grade PCM. Many of the aforementioned reviews reported only the phase change temperature and latent heat of fusion. In fact, the density, specific heat, and thermal conductivity of most phase change materials were not reported in the literature. We recently compiled a complete database of the thermophysical properties of PCM from the literature that can be found online [6]. It reports properties such as phase change temperature, latent heat of fusion, thermal conductivity, density, and specific heat for a large number of commercially available PCM and also for laboratory grade PCM reported in the literature.

Figure 1: Illustration of the ability of PCM to reduce the thermal energy through a building wall and to shift the peak thermal load to a time of day with a lower electricity rate. Figure 1: Illustration of the ability of PCM to reduce the thermal energy through a building wall and to shift the peak thermal load to a time of day with a lower electricity rate. |

Table 1: Characteristics of organic and inorganic PCM  |

Objectives

Understanding the effects of PCM addition on the thermal and mechanical behavior of building materials is essential to the design and control of smart multifunctional PCM-composite building envelopes. Our laboratory effort aims to (i) develop thermal and mechanical design tools for exploring the use of PCM-composite materials in smart multifunctional building envelopes, (ii) assess the potential energy and cost savings of buildings made with PCM-composites in any selected climate, and (iii) provide recommendations regarding the design and implementation of PCM-composite building walls.

References

- “Buildings and climate change: a summary for decision makers,” United Nations Environmental Programme, Sustainable Buildings and Climate Initiative, Paris, 2009.

- M. Levine, D. Urge-Vorsatz, K. Blok, L. Geng, D. Harvey, S. Lang, G. Levermore, A.M. Mehlwana, S Mirasgedis, A. Novidova, et al., “Residential and commercial buildings; contribution of working group iii to the fourth assessment report of the IPCC,” Cambridge University Press, Cambridge, United Kingdom and New York, NY, USA, 2007.

- United States Department of Energy, Buildings Energy Data Book, 2011, http://buildingsdatabook.eren.doe.gov.

- California Public Utilities Commission and Others, California long term energy efficiency strategic plan: achieving maximum energy savings in California for 2009 and beyond, San Francisco (CA): California Public Utilities Commission; 2008.

- UNEP SBCI, Buildings and climate change: A summary for decision-makers, Paris: United Nations Environmental Programme, Sustainable Buildings and Climate Initiative; 2009.

- B. Young, A.M. Thiele, L. Pilon, “Thermophysical properties of phase change materials,” 2014, http://www.seas.ucla.edu/~pilon/downloads.htm